The Design Observer Twenty | Sponsored by IDEO

The Design Observer Twenty is our curated selection of twenty remarkable people, projects, and big ideas solving an urgent social need.

And would designers feel differently about the work they do?

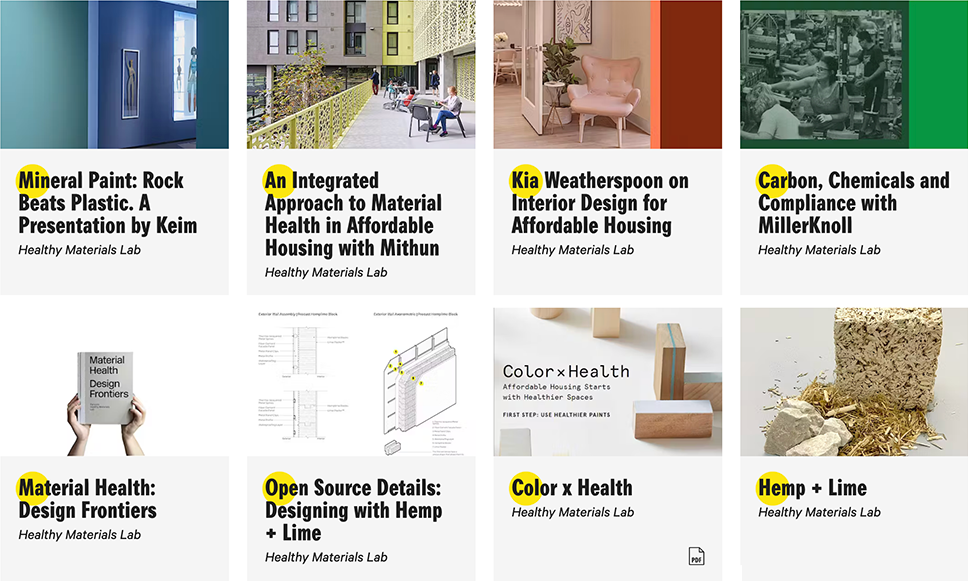

The Healthy Materials Lab (HML) at Parsons is a free resource for architects, designers, developers, manufacturers, students, and other stakeholders to better understand which building materials negatively impact the health of people and communities and how to avoid them. The lab offers classes, resource material, research, and technical insights designed to help practitioners make cleaner choices at every stage of development.

But it has also become an oasis for practitioners who want to fix what the industry has broken.

“I’ve had students come up to me in tears and say, ‘I don’t want to be a designer anymore,’” says Jonsara Ruth, co-founder and design director of HML. An associate professor and founder of the school’s MFA Interior Design program, she says that the building industry’s outsized contribution to waste, toxic chemicals, and greenhouse gas emissions is deflating to the rising generation of designers and architects. And plenty of established ones, too. “The impulse is to contribute positively to the world,” says Alison Mears, the lab’s director and co-founder, a Parsons professor, and a working architect. “So, a lot of the work we do is creating material collections — lists of products that we vetted for the ingredient content and performance. So, someone like me, an architect sitting at my desk with no time, can go to these lists and trust the products that are on there.”

The pair have narrowed their focus — and by extension, ours — to cleaning up the affordable housing industry, which has historically relied on cheap, subpar materials that negatively impact low-income communities. (Think lead pipes, paint made with dangerous chemicals, carcinogenic insulation, and the like.) “If we can make transformation in this space — educate architects and designers to do a better job — that’s our theory of change,” Mears says. The lab currently charts healthy affordable home projects across the U.S. through their healthy home dashboard, a dynamic map of good design news. “Housing offers stability to people who have been confronted with poverty and other disruptive issues,” she says. Their homes should not make them sick or unsafe. “These homes should be free of toxins. These homes should be beautiful.”

Mears and Ruth see their work as a gateway into a more extensive conversation about systemic racism in the supply chain and how dangerous chemical plants poison the air and soil of low-income “fenceline” communities — neighborhoods adjacent to and affected by the noise, emissions, traffic, and waste generated by heavy manufacturing or other industrial facilities. “If you make a better product, you improve the health of the people who live next to or work in that factory,” Ruth says. “This is a public health and pipeline issue.”

The lab has grown to a professionally diverse team of 19, and is working with a wide array of research partners like the Harvard Office for Sustainability, Center for Environmental Health, and the Danish Cleantech Hub; and funders like the JPB Foundation and the Angelo Donghia Foundation.

The dream is to get to scale, sustainably.

“Anyone can change one building, one house. You know, it’s not that hard to do that. But to do that a thousand times, ten thousand times, a million times over — is really difficult,” Mears says. But it’s also attainable, Ruth says. “It starts with changing the way people think about the decisions they’re making — we call it material health questioning. When you pick a thing up, what is it made of?” Better insights yield better decisions, and become guidelines that inform enduring sustainability standards. “That’s the ripple effect we’re looking for.”

Essay by Ellen McGirt.